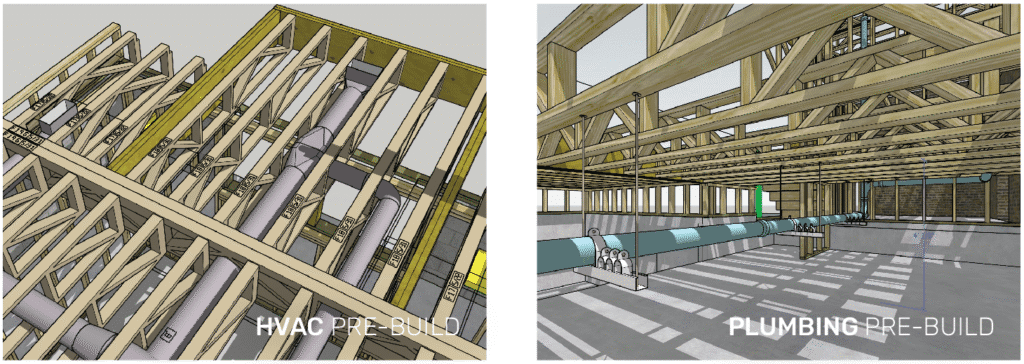

Our Digital Pre-Build Process

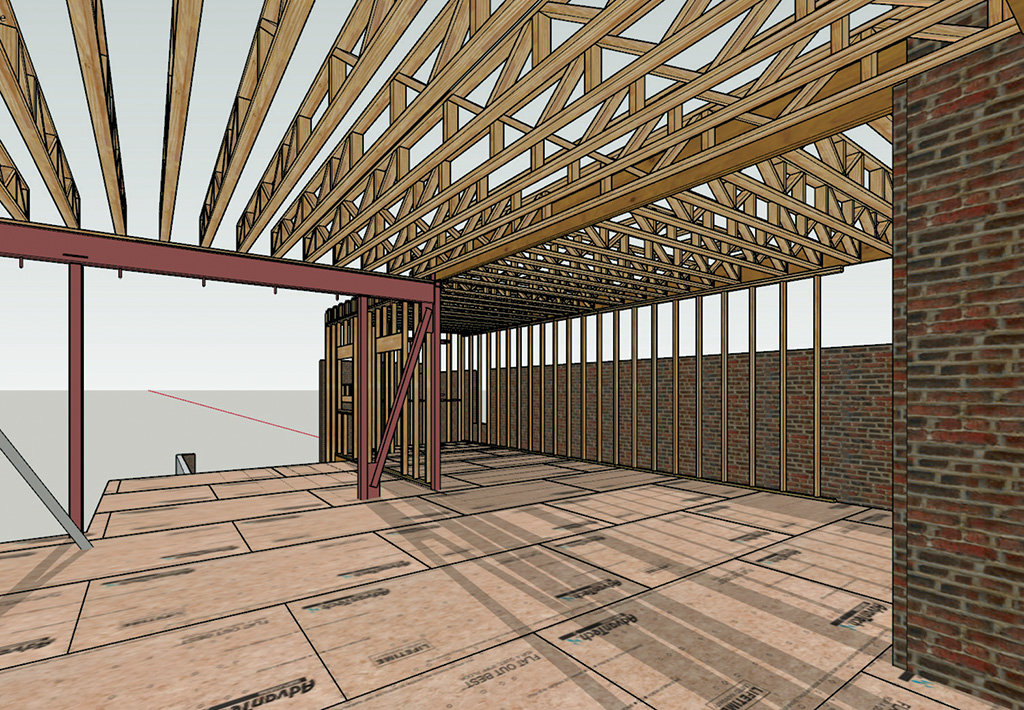

Over the past several years, we have utilized 3D modeling to address complex construction details. Fully modeling the entire project is the most effective approach to achieving the best possible project outcome.

What is pre-building?

Our approach mirrors the “measure twice, cut once” philosophy, much like the meticulous process Norm Abram followed on The New Yankee Workshop (PBS). A true craftsman, Norm would painstakingly recreate historic furniture pieces, studying every nuance and measurement to secure a faithful reproduction. Before filming, he would first build a prototype off-camera, working through mistakes and adjustments in private. Only after mastering the project would the cameras capture his expertise, showcasing the refined result. Inspired by this time-tested method, our pre-build modeling allows us to construct the project virtually first, ensuring that real-world construction comes together flawlessly from the start.

Our process:

Unlike BIM and AI solutions, which rely heavily on computer-generated analysis, the Kelly | Smith Construction’s pre-build process takes a distinct approach. While these technologies can appear convincing, they often contain gaps in project understanding and may yield inaccurate outcomes. In contrast, every element of our projects – from framing and mechanical ducts to sanitary lines and electrical fixtures – is thoroughly reviewed and resolved through our combined construction and design experience. We continuously update our methods with the latest industry standards and incorporate specialized insights from vendors and subcontractors to maintain clarity and precision throughout the process.

Why is pre-building is a better option?

Project Coordination

We are able to identify Requests for Information (RFIs) days, weeks, and sometimes even months ahead of the need for responses. This proactive approach virtually eliminates last-minute emergencies, hastily considered solutions, and a stressed project process.

Value Engineering / Cost Controls

While modeling the plans, cost-saving opportunities often emerge. Identifying these early provides ample time to review and consider the best course of action. This also allows us to perform in-house material estimating and develop highly detailed pricing exhibits for subcontractors. This accurate construction budgeting eliminates the fatigue of “nickel-and-diming” clients throughout the process.

Project Duration

Recognizing that time is a critical resource, our pre-building approach enables us to accelerate project schedules significantly, leading to substantial cost savings. By virtually eliminating labor standby time – often caused by waiting for information – we streamline workflows and identify more efficient installation methods.

In the right menu, click > Scenes > My Scenes